Quality Sheet Metal (QSM) offers extensive fabrication services for a multitude of projects ranging from single-use prototypes to large-scale production quantities.

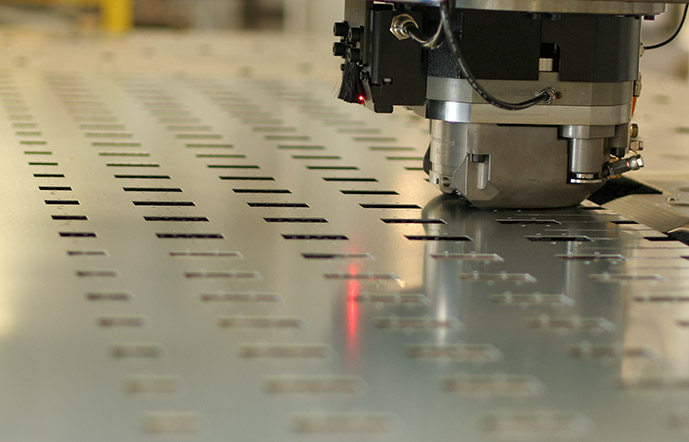

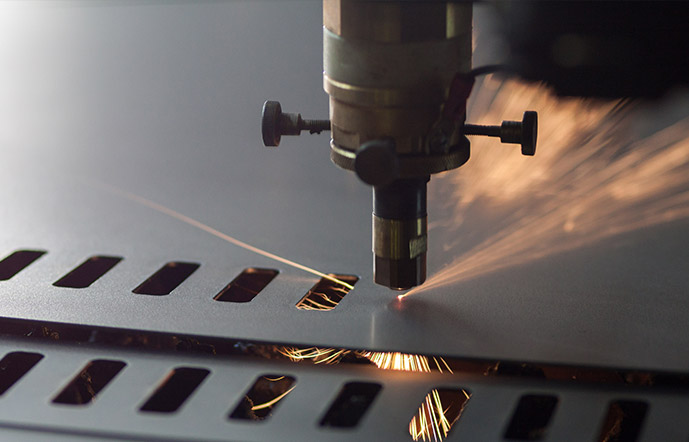

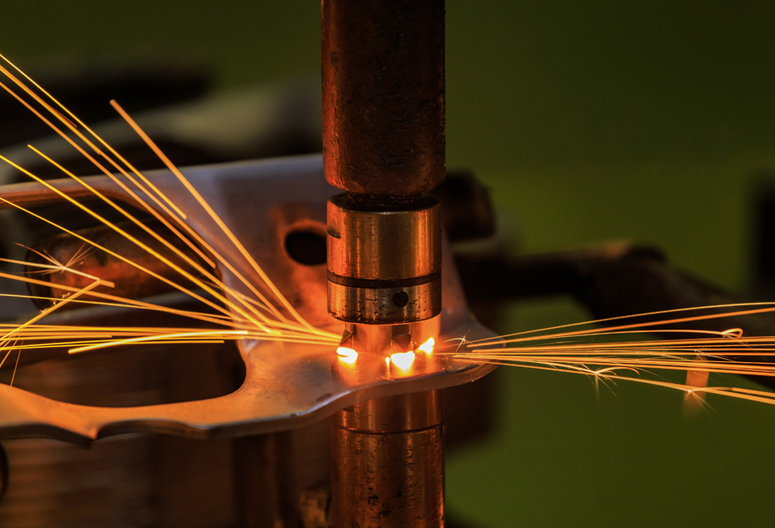

Using state-of-the-art equipment, our skilled technicians deliver precision parts, weldments, and assemblies for use across diverse fields, including the medical, electronics, pharmaceutical, transportation, and aerospace industries.

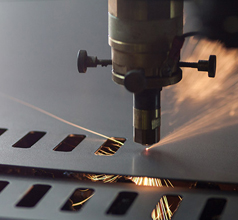

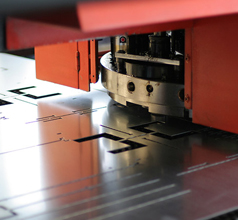

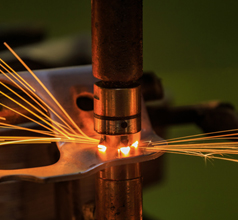

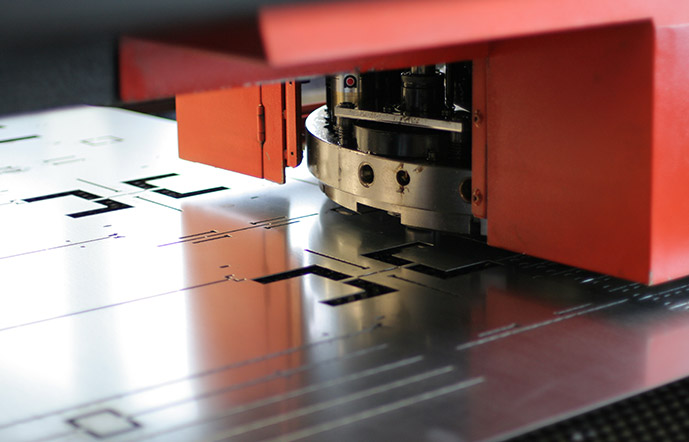

Through the use of advanced fabrication techniques such as CNC machining, laser marking, press braking, and other automated processes, QSM serves as a single source supplier for all of our customers’ metal fabrication needs.

Metal Fabrication Techniques

Our metal fabrication services produce unique products that offer cost and performance advantages over standard, off-the-shelf parts and components. Some of these fabrication techniques include: